New Wash Tanks Design for 2024/25

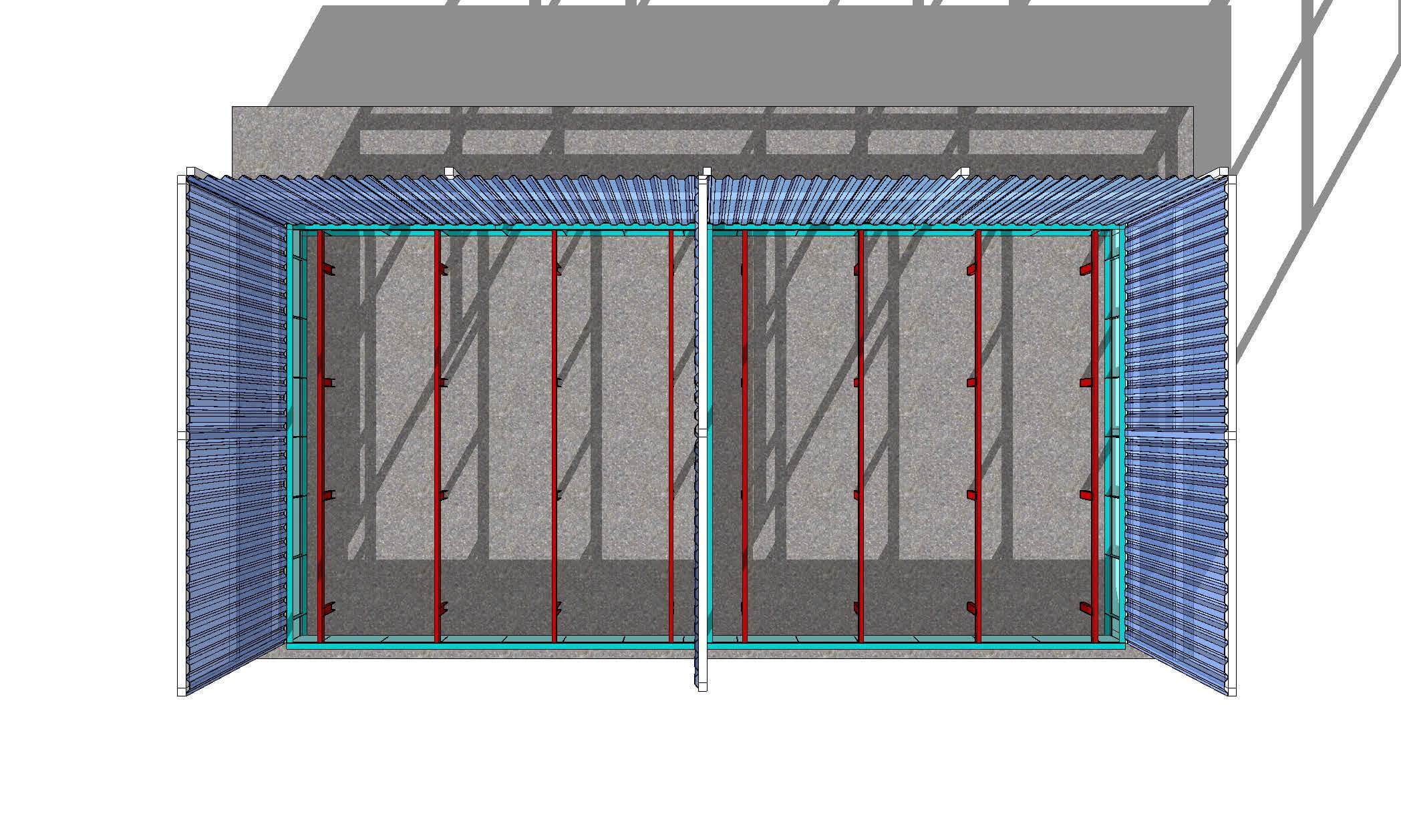

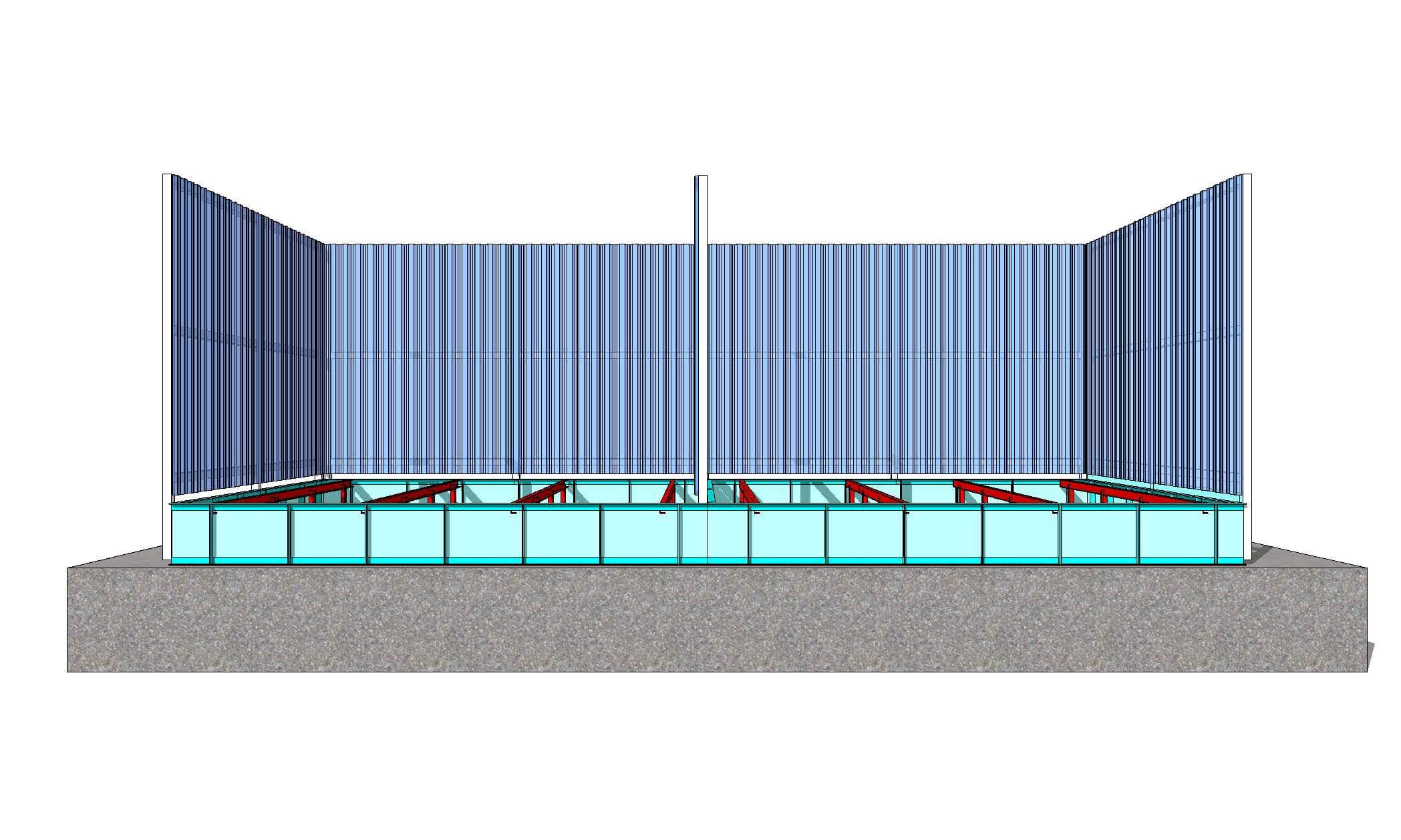

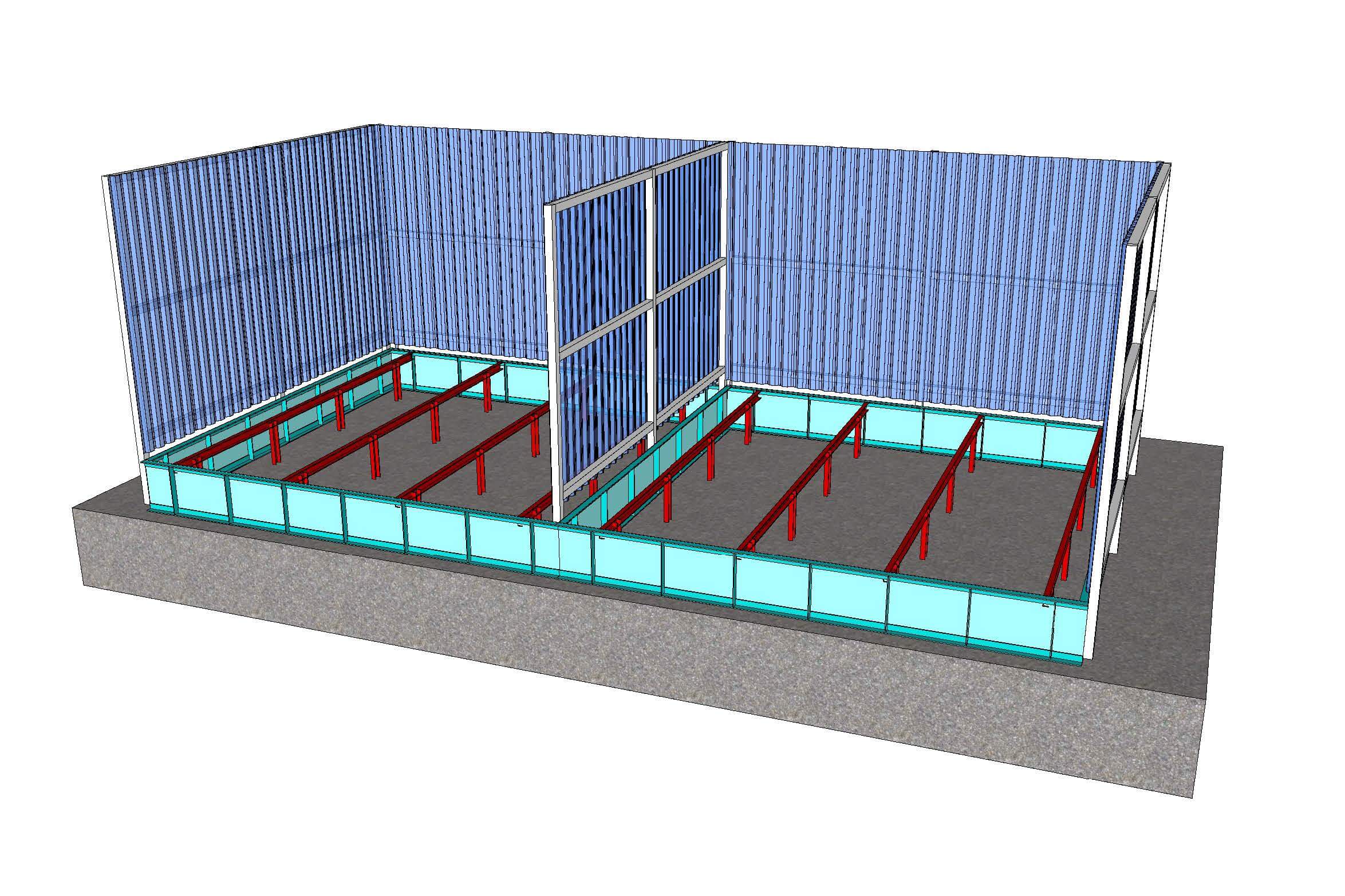

Introducing our new wash tanks design for 2024-2025. Utilising our own R&D department and 3D CAD, Morclean have re-designed their wash bay bunded tanks and made several improvements. The wash tank is a self-contained structure with a grating and side screens to protect passers-by and/or the environment for overspray. Ideal for washing plant an equipment, parts and components.

Wash tanks can be installed inside or outside and only requires a reasonably level concrete base or similar slab. Ideal for washing tanks, motors, engines, small plant, portable equipment, vessels, parts and accessories, providing a legal and compliant wash tank to contain the water and prevent any outflow to a surface drain

Improvements to the wash tanks design

The new Morclean above ground wash tank is now manufactured from recyclable polyethylene with a GRP grating. The side walls are manufactured from twin wall polycarbonate.

Advantages of the new tank design

- Polyethylene requires no painting or surface preparation, unlike steel.

- No rusting or deterioration of the surface due to marks and scratches

- No rusting of screws, bolts or seams where steel is welded

- Lighter to transport and maneuverer if relocated

- Resistant to chemicals and detergents

Used in conjunction with a Mondo™ or above ground interceptor, the wash tank therefore becomes a totally free standing and above ground solution with no requirement for excavation or groundworks. The system is bolted down to the floor but can be relocated if circumstances change on site and is semi-portable. Wash water collected from the wash tank can either be partially treated within the tank itself or outflow to a surface mounted interceptor. Where no mains foul drain is available, the contaminated water can be stored for disposal off-site or treated via a water recycling system.

Especially for internal use, the wash tank is now available with a cabinet-mounted hot water electrically heated high pressure cleaner, resulting in zero emissions.

Click below to view our full product guide. (opens in a new window)

Morclean’s quality administration systems have been assured and approved to the standards and guidelines of BS EN ISO 9000:2015 for the sales, service and hire of industrial cleaning equipment.

Our registration no. is 94/121120 and our standards and guidelines are externally audited by CIS.

- Please note that many models described on this website are bespoke, and as such cannot always be accurately depicted.

- All photographs and illustrations displayed on this website are representative of model ranges or a model series only. Individual models and specifications may vary from those shown.

- Please contact us if you require clarification or individual specifications of any equipment. Morclean reserve the right to update and amend the specification of our equipment and accessories without notice and in the interest of the customer.

- Images or specifications must not be reproduced with express written consent from Morclean Ltd.

- Any prices quoted are subject to VAT @ SR. E &OE

YOUR LEGAL REQUIREMENTS, DUTY OF CARE AND COMPLIANCE

Effluent and run-off from washing and cleaning activities can damage the environment and pollute rivers, streams, burns and groundwater. Dirt, brake dust, traffic film residue and oil that is washed off are all pollutants.

The cleaning agents you use (including those labelled biodegradable or traffic film removers) are very poisonous to river life. If you cause pollution, you are breaking the law and spoiling your environment. Dirty water or run-off from vehicle washing and cleaning carried out as a business or industrial activity is called trade effluent.

Whether you’re cleaning just one vehicle or responsible for a large lorry fleet, you must arrange for collection and disposal of effluent to prevent pollution. It’s illegal to discharge trade effluent to the environment or into drains without permission.

A selection of general and typical requirements for the containment and safe disposal of wash water are shown below

Activities that produce run-off from the vehicle onto the ground and use cleaning and valeting products should be carried out in areas that are clearly marked and isolated from surface water drainage systems, unmade ground and porous surfaces. These areas are called designated washing bays. A designated washing bay should be designed so that run-off is:

- isolated using channels, gullies, gradient (fall on the surface) and kerbs

- directed to a silt trap or settlement tank to remove larger particles of silt and sediment

- either collected in a sealed system for reuse, discharged to the public foul sewer with prior permission of the local sewer provider or collected in a sealed system for authorised disposal

You should also:

- have procedures for everyone, including contractors, that cover where and how vehicle washing and cleaning should be carried out and what to do in a spillage emergency

- provide notices for designated washing bays saying what they’re for and that washing and cleaning should only be carried out in the bay • consider whether a fence or barrier is required to prevent spray or wind drift out of the designated area

- have procedures and equipment which minimises water use and solid waste production

Understanding your drainage system is the key to preventing pollution. Most areas have what is known as a separate drainage system where there are two types of drain:

- Surface water or clean water drains should only carry uncontaminated rainwater; they lead directly to ditches, streams, burns, rivers and soakaways. Roof water, car park, road and some yard drainage is usually connected to the surface water drainage system

- Foul water drains carry contaminated water (sewage and/or trade effluent) safely to a sewage treatment facility, which is either owned privately or by the local sewage treatment provider. Any system designed to carry foul water is called a foul water drainage system

- Drains (surface water and foul) are also known as sewers. Your local sewer provider is the organisation with the legal responsibility to provide public sewerage and sewage treatment facilities in your area. Drains owned by the local sewer provider are known as mains drainage, main sewers or public sewerage systems

The Morclean bunded wash tank provides a compliant solution, namely an isolated, bunded and water tight method for the containment of contaminated wash water.

Wash tanks are sealed to safely capture and contain wash water

Our wash tanks are sealed with a steel flashing to ensure all wash water is captured and safely contained within the wash bay area. Our installation team ensure that the wash bays are water tight and fit for purpose, and our ‘in-house’ engineers have years of experience in water treatment and containment

2024 Wash Tank Technical Detail

Standard Capacities & Dimensions

Morclean have also standardised the weight bearing capacity of the gratings and on the assumption that the objects being washed are evenly distributed, then the below can be used as a guide

| Standard max weight | Up to 3T |

| Medium Max weight | Up to 5T |

| High max weight | Up to 12T |

Wash tanks can be manufactured in any practical and reasonable size from 1M x 1M to the below typical dimensions.

Typical footprint sizes – please note wash tanks can be made to any practical size

| 3 x 2M | 1 x 1M |

| 5 x 3M | 3 x 3M |

| 6 x 4M | 4 x 4M |

| 3 x 3M | 6 x 6M |

Generally the wash tanks are made to a depth of 400mm for FLT loading and unloading, and to provide a reasonable working hight for the operators wash lance, though can be manufactured to any height from 100mm to 500mm

| Min height | 100mm |

| General working height | 400mm |

| Max height | 500mm |

Wash Tanks: Manufactured from steel, galvanised to EN 150 1461:2

The Morclean wash tank is self-contained and over spray is restricted using polycarbonate screening to three sides. Components are placed on the open mesh grating and the contaminated wash water falls into the base tank where it is settled. Depending on the dimensions and the application the base tank and sump can be designed to incorporate an interceptor which, in turn, saves space and the need for excavation to install a secondary interceptor.

Wash Tank Applications

Wash tanks are ideal for washing parts, components, garden machinery, small plant, engines, portable equipment etc; where parts – contaminated with oils, grease or harmful substances – have to be washed in a sensitive area. Past projects include; parts from oil rigs, wheelchairs and walking aids from hospitals and components from mining, shipping, gas, aerospace, quarrying or oil industries.

| Item | Dimensions |

| Base Tank | 6mm fully welded |

| Base | 300mm/400mm |

| Flooring | 1000mm open mesh |

| Posts | 80 x 80 x 5mm SHS |

| Screens | Polycarbonate |

Wash Tank Design

The general design is made up of a 6mm base tank which is fully welded and typically 300mm to 400mm deep. The internal structure of the tank is designed to act as a silt trap and the outlet is positioned on one of the base sides.

The open mesh flooring has removable grating to ease access and cleaning while the top of the tank features chequer plate flooring all supported by associated steel supports (determined by the max load of the items to be placed on the grating).

Side screens to protect from overspray are supported by 80mm x 80mm x 5mm SHS posts and typically 2m in height, and clad with polycarbonate screening fixed between the supporting posts.

All the above steel is galvanised to EN 150 1461:2.

In addition to the above a control panel can be fitted to either side of the wash tank and the system can incorporate a Morclean hot or cold-water pressure wash of up to 3000Psi.

Specifications dependant on max loading placed on the base tank and mesh floor. Larger models and sizes also available and due to transportation these may need to be made 2 sections and lifted by HIAB and offloaded to a position onsite.

| 2m Wash Tank | 3m Wash Tank | |

| Length | 2m | 3m |

| Width | 3m | 4m |

| Height | 2m | 2m |