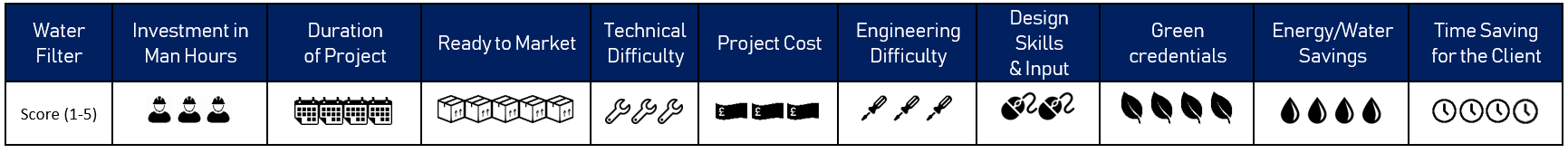

Water Filtration

As well as the projects listed below, Morclean have also developed several prototypes for niche and specialist water filtration applications. This particular project is a portable water recovery platform to re-use water, within the limitations of space and locations. Water used during the washing of plant and equipment can be recovered and re-used, typically for builders merchants and hire firms in temporary locations

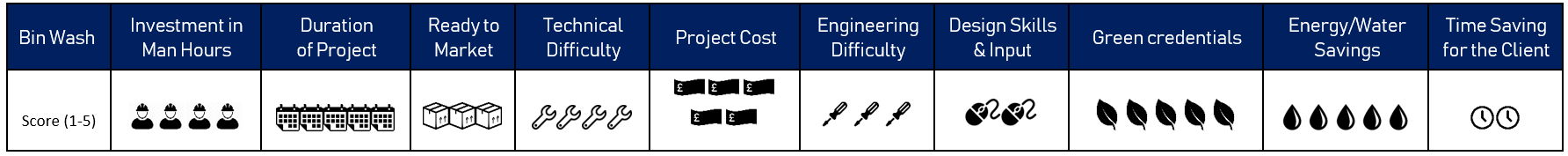

Battery Driven Bin Wash

Design and development of our multi-award winning Carbon/C02 Free Battery Driven CITY Bin Wash. The combination of effective high-pressure cleaning and reduced costs, fuel usage and CO2 emissions, has been an innovative step forward for this industry. The Morclean CITY Bin Wash provides operators and communities with a smarter, greener, cleaner solution to a dirty problem and we have the Green Apple awards to prove it!

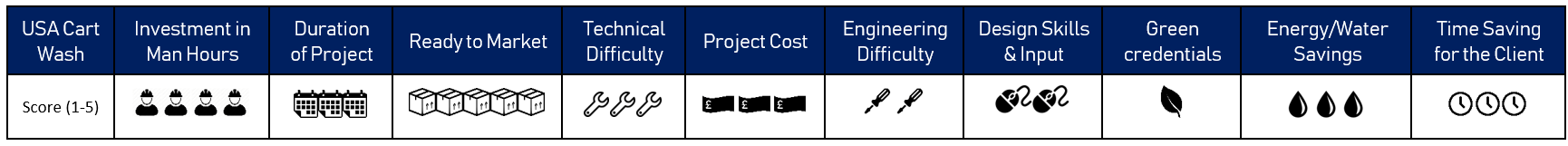

NEW USA Cart Wash

Morclean are always looking at the development of new Bin Wash models. 2017 Saw the production of our new TR200 cart wash, which is only available in Canada and the USA. With the TR200 came the development of our new, approved lift mechanism which complies with ANSI Standards. Morclean have also designed and produced a UK XL version, with features such as a safety platfrom to ensure the operator is safe when on the roadside.

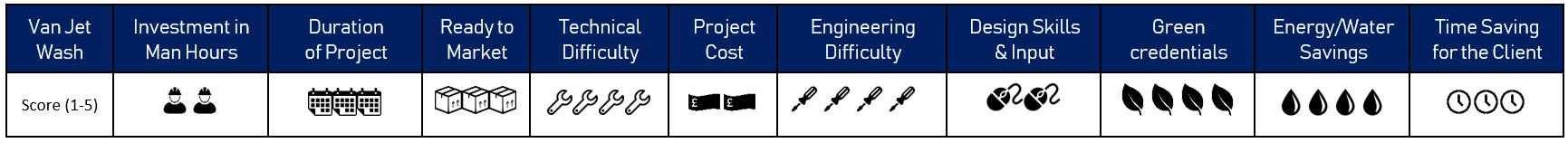

Van Mounted Jet Wash

(No Engine Needed)

Developing a forward thinking prototype of a 1500 PSI Hot Water Jet Wash, which runs from the energy provided by the vehicle, thus requiring no independent engine, battery or generator to power it. This prototype is designed for emergency clean ups and will efficiently aid in dealing with problems such as emergency spill cleaning, trauma and crime scene cleaning, sewage spills and more.

Bin Wash Water Filtration

New and unique to the market place, a handful of Morclean Bin Wash machines are using silver impregnated carbon to inhibit growth of bacteria in waste water, while using the idling energy from the existing machine to re-filter the water. This means no additional power, pumps or battery etc are needed. This water filtration system is currently fitted to the Custom and 40 Bin Wash models.

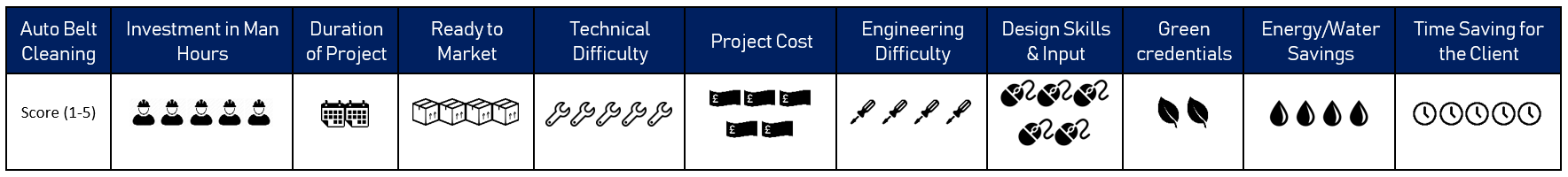

Automated Conveyor Belt Cleaning

Design and development of our multi-award winning Carbon/C02 Free Battery Driven CITY Bin Wash. The combination of effective high-pressure cleaning and reduced costs, fuel usage and CO2 emissions, has been an innovative step forward for this industry. The Morclean CITY Bin Wash provides operators and communities with a smarter, greener, cleaner solution to a dirty problem and we have the Green Apple awards to prove it!

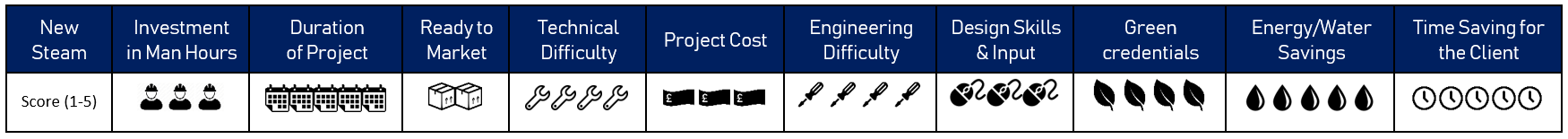

NEW Steam Technology

Morclean are always looking at the development of new Bin Wash models. 2017 Saw the production of our new TR200 cart wash, which is only available in Canada and the USA. With the TR200 came the development of our new, approved lift mechanism which complies with ANSI Standards. Morclean have also designed and produced a UK XL version, with features such as a safety platfrom to ensure the operator is safe when on the roadside.

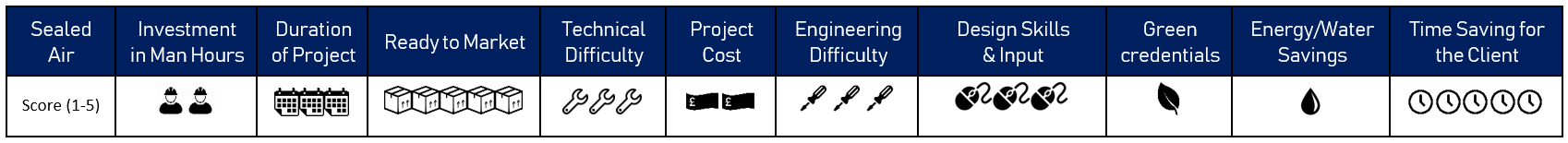

Sealed Extraction Vacuums

We are testing and developing our Morclean AIRTEC vacuum machines, which extract steam and other vapours that would normally pass through the air vents on a standard vacuum cleaner.

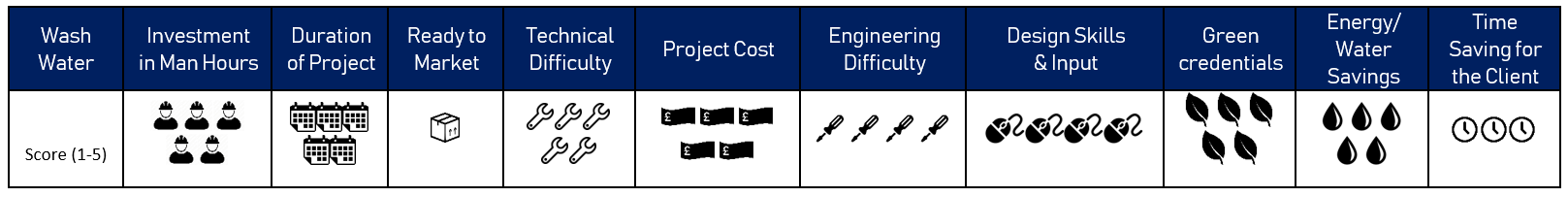

Wash Water Filtration

New and unique to the market place, a handful of Morclean Bin Wash machines are using silver impregnated carbon to inhibit growth of bacteria in waste water, while using the idling energy from the existing machine to re-filter the water. This means no additional power, pumps or battery etc are needed. This water filtration system is currently fitted to the Custom and 40 Bin Wash models.

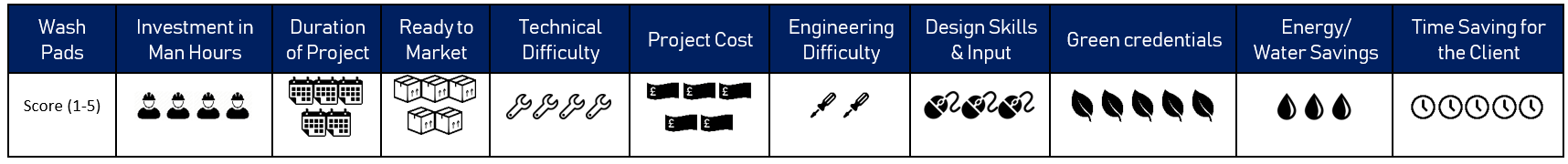

Wash Pads

Morclean have developed and producted an award winning, surface-mounted wash pad system, for use in the car and vehicle was industry. The system is surface mounted, which eradicates the need for any ground works or excavation, making it cost effective for the client. The Wash Pad can also be re-located if needed and satisfies current legislation for the containment and disposal of water.

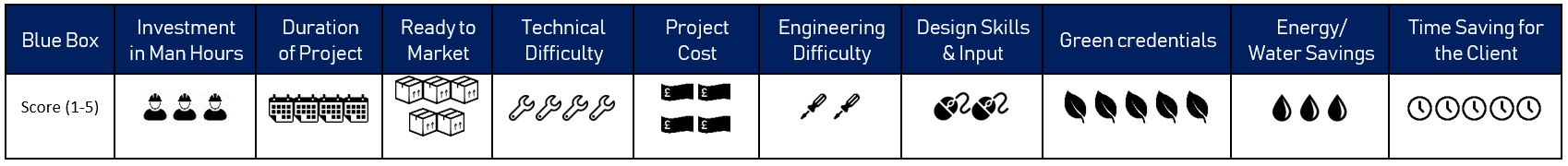

BlueBox/GreyBox

With an innovative design, specially made for quick installation with minimum inconvenience.This means there is no requirement for excavation or ground works to install, like there would be with an interceptor. Our Blue and Grey boxes are designed to be semi-portable so can be moved from site to site if needed. The two systems provide containment and partial treatment of waste, wash water prior to outflowing to a foul drain.

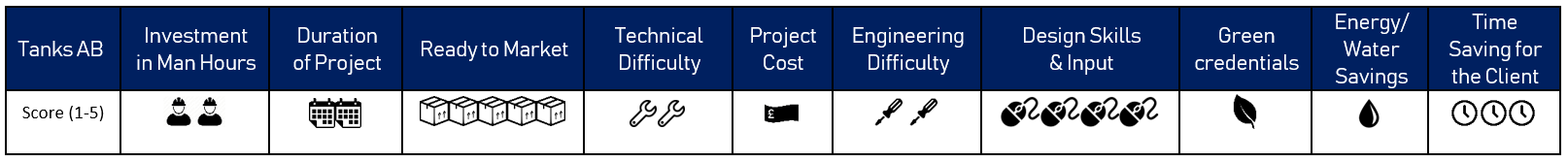

Water Supply Tanks with Type AB Air Gap

Reacting to demands of clients, where water storage requirements and legislation dictate that an air gap must be present in a water storage tank to prevent back flow. Typically used for supplying multiple jet washes or volume wash pumps and up to 20M3

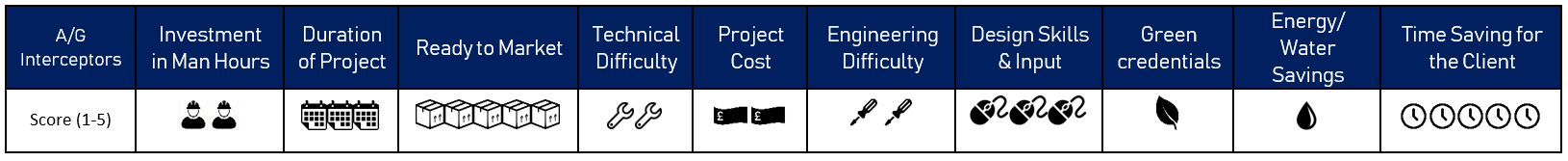

Above Ground Interceptors

Production of modular above ground MONDO interceptors to eliminate the need for excavation or ground works. An aesthetically pleasing design in any RAL colour to blend in with client’s site. Typically used as a separator for larger car wash and lorry wash applications

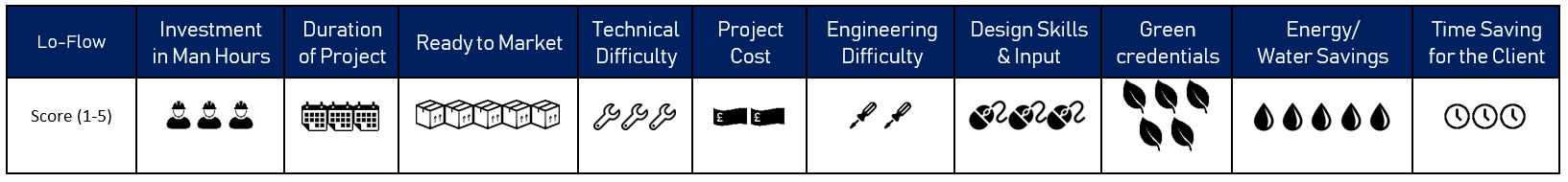

LoFlow Pressure Cleaners

Develop and produce a range of LoFLow hot water high pressure cleaners, which use less than a third of water a traditional jet wash would typically use. Equivalent kW energy at the cleaning nozzle using 5 LPM versus a traditional 15 LPM jet wash. This system uses less water and clean energy to produce hot water with zero emissions.

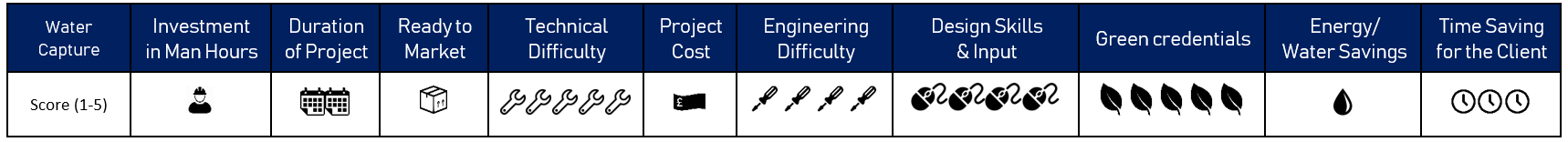

Water Capture

Initial trials and investigation into a portable water capture system called Vacuboom, where we will further develop and improve what’s available on the market today.

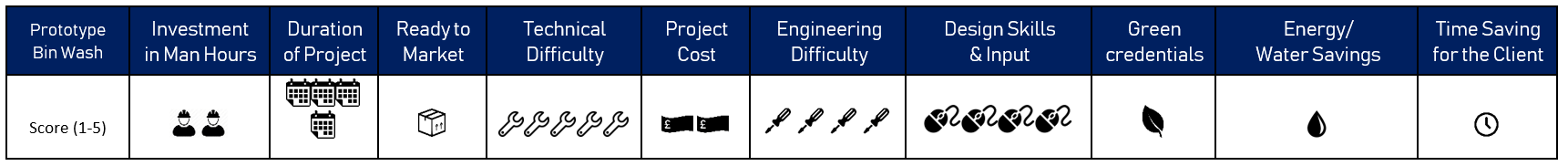

NEW Bin Wash Prototype

We are trial and testing new technologies and methods to integrate into our wide range of Bin Wash machines, by using CAD design and physical building of prototypes for the future. Presently ‘undercover’ with no public info available to protect the I.P. No further information until ready to market.

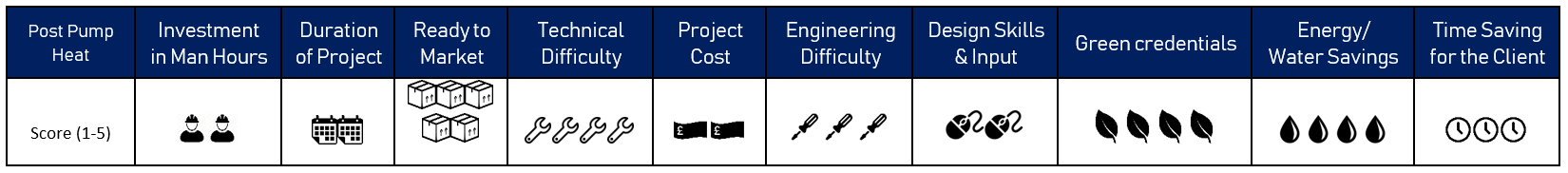

Post Pump Water Heating

Design development and production of hot water high pressure cleaners utilising post pump heating. The system provides constant hot water with no temperature fluctuations whilst being fume free and producing zero emissions. Post pump heating also reduces the general wear and tear of pumps and seals, whilst only producing hot water on demand, in order to reduce waste energy and water.