Surface-Mounted Wash Pads

Morclean’s surface-mounted wash pads are innovative solutions designed to facilitate vehicle washing while ensuring environmental compliance and operational efficiency. These systems eliminate the need for excavation or below-ground installations, making them ideal for various settings, including leasehold or sensitive sites where traditional concrete wash pads may not be feasible.

Key Features:

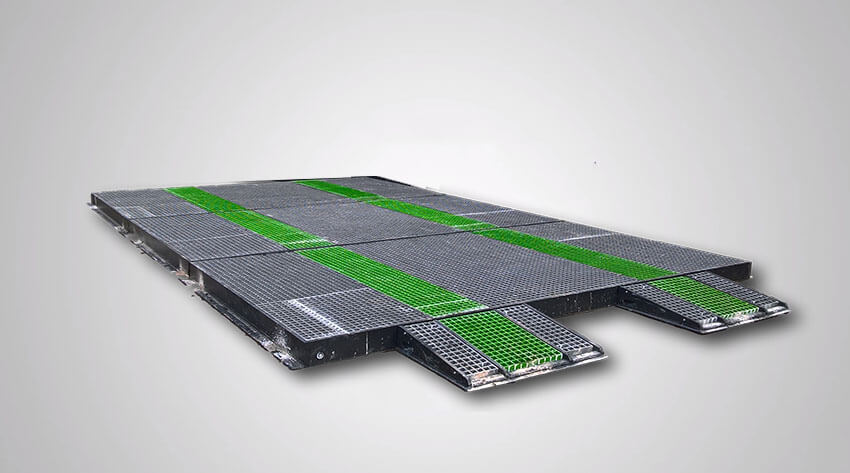

Sealed Bund Construction: The wash pads are constructed from a combination of welded plastics and fiberglass panels, creating a solid, impermeable containment area. This design ensures effective capture and management of wastewater during vehicle washing operations.

Surface-Mounted Installation: Being surface-mounted, these wash pads require no excavation, allowing for quick and cost-effective installation. This feature is particularly beneficial for sites where groundworks are impractical or prohibited.

Durable and Low-Profile Design: With a low-profile external raised curb approximately 100mm – 150mm high, the wash pads minimize the risk of accidental damage from vehicles entering or exiting the pad. The external gratings are easily removable, facilitating straightforward cleaning and maintenance.

Water Management Integration: The system captures all wastewater into a drain equipped with a surface-mounted sump pump. The collected water can be discharged to a foul sewer, partially treated via Morclean’s BlueBox or GreyBox systems, or directed to a water reclaim system, promoting sustainable water use and compliance with environmental regulations.

Surface-Mounted Wash Pad Gallery

General Surface Mounted Vehicle Wash Pads Operation

The rigid permanent mat is positioned after delivery and installed with suitable fast fix bolts to fix to the floor (Morclean provide delivery installation and transportation using their internal transport).

If using a drain and pump the site does not require any excavation and Morclean can supply all items to be surface mounted.

Then simply drive the vehicle on to the wash pad and you have a fully fitted wash pad at a fraction of the cost, disturbance and time. We can design and manufacture to any practical size.

The wash platform will not be damaged by the weight of the vehicle it is designed for. This is a tested product that has taken several years to develop.

Commitment to Quality

Although innovative and easy to operate the wash pads are more than just a simple construction. All wash pads have to be fully tested and we guarantee water-tightness of the floor. All welded joints and connections are vacuum tested and inspected during a quality procedure. Every wash pad is given a unique registration number to ensure the identification of all the products used during construction.

Technical Specifications

Standard Sizes 5m x 3m or 6m x 4m (Standard). Morclean offers bespoke design and build options to accommodate specific site requirements.

Permitted Weight Specifically designed to support the weight of the heaviest vehicles or equipment in a fleet, ensuring robust performance across various applications.

Colour Options Standard colour options include grey and green. Other colours available upon request to suit specific aesthetic or branding preferences.

Feature Fibreglass gratings to make a solid liquid containment tray.

Maintenance All gratings removable for ease of servicing maintenance and cleaning.

External Fitted with low profile external raised kerb approx. 100mm – 150mm high (to prevent accidental damage if vehicles drive off the ramps).

Applications and Benefits

Versatility: These wash pads are suitable for heavy-duty environments with high vehicle washing volumes, such as car auctions, dealerships, and hand car wash facilities.

Environmental Compliance: By effectively containing and managing wastewater, the wash pads help businesses comply with environmental regulations, preventing the unauthorised discharge of pollutants into surface waters or groundwater.

Operational Efficiency: The quick installation and minimal site disruption associated with surface-mounted wash pads enable businesses to maintain continuous operations without significant downtime or site modifications.