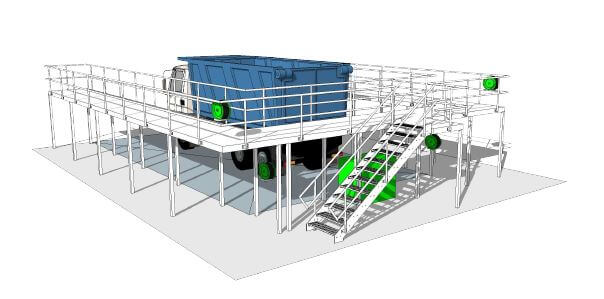

Fixed Gantry Wash

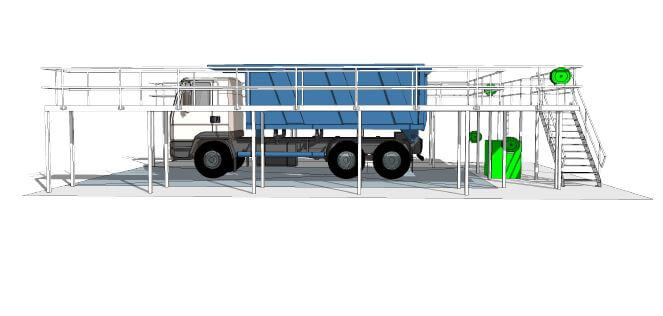

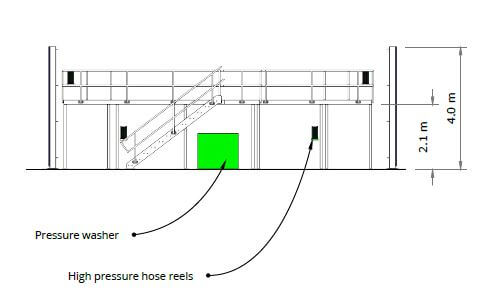

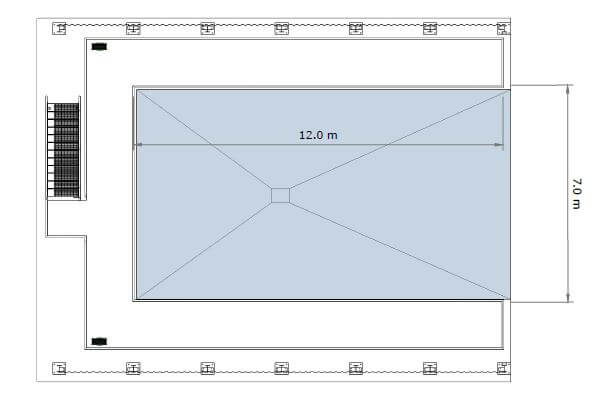

The Morclean Fixed Gantry Wash System is designed for the cleaning of irregular sized and shaped vehicles, using hot or cold water, and fully installed pipe work around the system. This provides access to high or irregular sized vehicles and is ideal for Transport, Waste Management or Plant. The pump unit, fuel and detergent is housed in a separate building and the system can be housed in a screen (SWS) to protect the surrounding area.

The Fixed Gantry Wash is semi-automatic and one operator can access all the features without the need to either enter the plant room, switch on the unit, or the need for trailing cables and hoses. The operator can access high sided vehicles from the upper level of the walkway, and plug in to a conveniently placed point to access the required pressure etc. Fixed Gantry Wash Fixed Gantry Wash Fixed Gantry Wash Fixed Gantry Wash

Fixed Gantry Wash Bay features include:

- Healthy and safe alternative to manual chassis cleaning

- Up to 4 times more productive than manual cleaning

- Measurable cost savings

- Total quality control

- Improved working conditions for vehicle technicians

- More vehicles cleaned more frequently, resulting in improved maintenance and earlier fault detection

- Accurate forecasting of chassis cleaning costs possible following installation

Varying options are available to suit both customer and site requirements, for example:

By-laws Compliance – Water Boost Set

The water by-laws compliance – boost set is constructed from a 227 Litre plastic tank incorporating the required air gap between stored water level and the town water supply, water inlet float valves and required overflows.

One off centrifugal boost pump is connected to the storage tank to supply the high-pressure triplex Cat pump located in the pump module with water at the correct flow and pressure for optimum performance and reliability.

Water level is controlled by means of a float valve. A low level float switch is fitted in the storage tank to stop all pumps from operating. The tank and associated pipe work is adequately protected against frost damage.

Detergent Application

There are two options offered for the application of detergents:

- before high-pressure washing (foam application) and

- during high-pressure washing (detergent injection).

Remote Cable Winding Drum

For use with pit mounted installations and where it is not practical to locate pump module and drive unit in the same area.

Hot Water Module

Purpose built self-contained 3-pass heat exchanger to provide 45 ltrs/min or 90 ltrs/min at 70°C oil or gas fired.

Fitted with Nu-Way or Selectos burners housed in lightweight fibreglass cover.

Note: all exhaust gas flue ductwork is to be supplied and installed by the customer.

CAP002 Automatic Frost Protection

If temperatures fall below the pre-determined value set on the frost stat, a solenoid valve is operated allowing all water to be blown from the high pressure hoses by compressed air for an adjustable time.

The activation of the frost protection system disables the use of the equipment until the frost stat has reset.

CHG001 Hand Lance System

Trigger operated hand lance, complete with high pressure hose for manual cleaning.

High pressure water is diverted from the pump module for use with the hand lance.

CJ 2000/10/

45 ltrs/min (10gpm) @ 130 bar (2000 p.s.i) generated by high pressure CAT pump, driven by 11Kw 415v 50Hz motor.

Fitted with preset safety valve, adjustable pressure regulator and pulsation damper.

Zinc plated or galvanised fabrication housed under fixed fibreglass lightweight cover.

CJ 2000/20/

90 ltrs/min (20 gpm) @ 130 bar (2000 p.s.i) generated by 2 off high-pressure CAT pumps, driven by 2 of 11Kw 415v 50Hz motors.

Fitted with sealed tamperproof safety valve, adjustable pressure regulator and pulsation damper.

Zinc plated or galvanised fabrications housed under fibreglass lightweight cover.